Maintaining ideal mesophilic (30–40°C) temperatures inside the digester is essential for winter biogas production, although this can be difficult in cold weather because of lower ambient and slurry temperatures. Using solar thermal or greenhouse systems for heating, storing feedstock to attain higher temperatures, integrating waste heat from other sources, and insulating are some ways to maintain or raise digester temperature and enhance winter productivity. Read on to find out more!

Key Takeaways

- Winter temperatures can easily reduce biogas production by 50-70% due to the temperature-dependent nature of anaerobic digestion.

- The relationship between temperature and biogas yield follows a cubic pattern, with production dropping dramatically below 15°C.

- Proper insulation strategies like underground placement and Styrofoam wrapping can maintain digester temperatures and minimize winter production losses.

- BiogasConnect's monitoring systems help plant operators track temperature fluctuations and optimize production during cold months.

- Strategic timing of substrate additions and cold-adapted bacterial communities can significantly improve winter biogas yields.

Biogas production plummets when temperatures drop. This renewable energy source, while promising for sustainable energy generation, faces significant operational challenges during colder months that can threaten both reliability and profitability.

Winter creates a perfect storm of problems for biogas plant operators, with temperature drops being the primary culprit behind reduced output. At BiogasConnect, we've monitored facilities experiencing production declines of 50-70% during winter months compared to summer peaks. Understanding these challenges is crucial for implementing effective solutions that maintain consistent energy production year-round.

Seasonal variations dramatically affect biogas digesters, particularly in regions with substantial temperature fluctuations. Studies from Northern Vietnam and mountainous subtropical regions show that simple digesters without heating systems become significantly less productive during winter. This temperature dependence makes biogas a less reliable energy source precisely when energy demands often increase.

Cold Reality: How Winter Slashes Biogas Output by Up to 70%

Winter's impact on biogas production is severe and immediate. Research conducted across various climatic zones consistently demonstrates that biogas yields from unheated digesters drop by 50-70% during cold months. This dramatic reduction directly correlates with falling ambient temperatures and their effect on the internal temperature of digesters.

A study in Northern Vietnam found that biogas production during August-October (summer) was substantially higher than in December-January (winter). This drop occurs because the microorganisms responsible for anaerobic digestion become increasingly inactive as temperatures fall below optimal ranges. The relationship isn't linear—it's cubic—meaning small temperature drops can cause disproportionately large production declines.

Even underground digesters, which benefit from soil's natural insulating properties, experience significant production drops when winter air temperatures plunge. The soil itself cools over extended cold periods, eventually transferring that chill to the digester contents. Simple biogas systems without supplementary heating become particularly vulnerable, with some nearly ceasing production during extended cold snaps. For more on how these systems work, explore the anaerobic digestion process.

Why Temperature Drops Devastate Biogas Production

Temperature is the single most critical factor affecting biogas production. Unlike some biochemical processes that merely slow down in cold conditions, anaerobic digestion fundamentally changes at different temperature ranges, with distinct microbial communities dominating at different thermal levels. These temperature-dependent dynamics explain why winter poses such a formidable challenge.

Most agricultural and small-scale biogas digesters operate in the mesophilic temperature range (20-45°C), with optimal production occurring between 35-38°C. When temperatures drop below 20°C, production begins declining significantly, and below 15°C, gas yields can drop to minimal levels. This temperature sensitivity makes maintaining internal digester heat the primary winter challenge.

Temperature-Dependent Microbial Activity

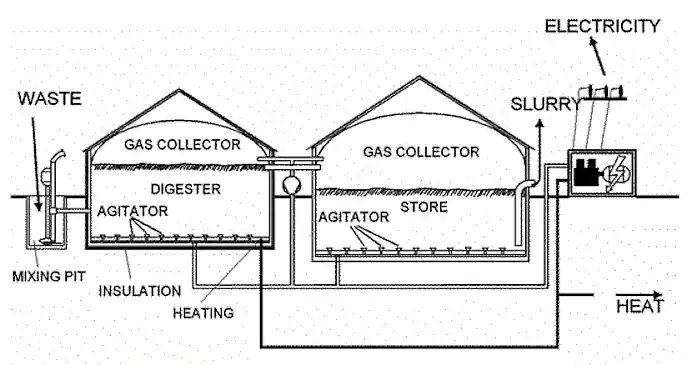

The biogas production process relies on four interdependent microbial stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Each stage involves specialized microorganisms with distinct temperature sensitivities. Methanogenic archaea—responsible for the crucial final step of converting acetate to methane—are particularly temperature-sensitive and become severely inhibited in colder conditions.

These methanogens operate optimally between 35-38°C for mesophilic systems and 50-60°C for thermophilic systems. When winter temperatures push digester environments below these ranges, methanogen populations decrease dramatically. Even brief cold periods can disrupt the delicate microbial balance, requiring days or weeks for full recovery once temperatures rise again.

The cascading effect of temperature on microbial communities explains why production doesn't simply slow proportionally with temperature drops. Instead, certain key microbial populations effectively cease activity altogether, creating bottlenecks in the digestion process that dramatically reduce overall gas yields.

Cubic Relationship Between Temperature and Biogas Yield

Research has established a cubic relationship between temperature and biogas production in the range of 10-30°C. This non-linear relationship means that small temperature changes have increasingly dramatic effects as temperatures drop. For instance, a 5°C drop from 20°C to 15°C might reduce production by 30%, while another 5°C drop from 15°C to 10°C could slash yields by an additional 50%.

Temperature Impact on Relative Biogas Production

30°C: 100% of optimal production

25°C: ~80% of optimal production

20°C: ~60% of optimal production

15°C: ~30% of optimal production

10°C: ~10% of optimal production

Below 10°C: Minimal production with potential system failure. For more information on how temperature affects biogas systems, you can read this article on winter biogas production.

This cubic relationship has been incorporated into numerous kinetic models of biogas production. The models consistently show that maintaining temperatures above critical thresholds is far more important than achieving perfect optimal temperatures. Preventing digesters from falling below 15-20°C becomes the primary goal for winter operation.

Critical Temperature Thresholds for Different Digester Types

Different digester designs have varying temperature thresholds that determine their winter performance. Simple plug-flow digesters typically experience operational difficulties at temperatures below 15°C, while completely mixed digesters might maintain minimal function down to 10°C. High-rate systems with fixed-film or granular sludge can sometimes operate at slightly lower temperatures but still see dramatic efficiency losses.

For household-scale digesters common in developing regions, the temperature threshold is particularly critical. These systems typically lack sophisticated heating mechanisms and rely heavily on ambient conditions. Studies in Northern Vietnam demonstrated that household digesters essentially stopped producing usable gas quantities when internal temperatures dropped below 12°C for extended periods.

Commercial-scale digesters often incorporate heating systems but still face significant energy balance challenges in winter. The energy required to maintain optimal temperatures can consume an increasing percentage of the biogas produced, creating diminishing returns as outside temperatures drop. Finding this balance point becomes crucial for winter operations.

Beyond Temperature: Other Winter Challenges for Biogas Plants

While temperature drops represent the primary winter challenge, several other cold-weather factors compound the difficulties for biogas operators. These additional challenges can sometimes be overlooked when focusing exclusively on heating solutions, yet they require specific mitigation strategies to maintain production efficiency.

Freezing of Pipes and Equipment

Sub-freezing temperatures create immediate physical hazards for biogas systems through freezing of critical components. Gas collection pipes, pressure relief valves, condensate traps, and effluent discharge lines are particularly vulnerable to freezing. When these components freeze, they can cause pressure buildups, blocked flows, and equipment damage that leads to extended downtimes.

Moisture in biogas itself presents another freezing risk. As gas cools in collection systems, water vapor can condense and subsequently freeze, creating blockages that prevent gas flow. Without proper condensate management and freeze protection, these blockages can completely halt gas collection even if the digester continues producing.

Substrate Quality Changes in Winter

Winter often brings changes to substrate quality and availability that further impact biogas production. For agricultural systems, animal feed changes during winter months can alter manure composition. Feeding increased hay and silage rather than fresh forage typically results in manure with higher lignocellulosic content, which is more difficult to digest and yields less biogas per unit volume.

Substrate temperature also plays a crucial role. Cold substrate introduced into a digester creates temperature shocks that can temporarily inhibit microbial activity. Each addition of near-freezing feedstock requires significant energy to heat to digester temperature, creating thermal stress zones within the digester that reduce overall efficiency until temperature equilibrium is restored.

Increased Energy Consumption for Plant Operation

The energy balance of biogas plants shifts dramatically during winter. Heating requirements increase precisely when production efficiency decreases, creating a challenging economic equation. Studies indicate that heating energy requirements can increase by 200-300% during cold periods, potentially consuming 30-40% of the total energy produced by the system.

This increased energy demand affects not just heating systems but also pumping and mixing equipment. Colder, more viscous substrates require more pumping energy. Mixers must work harder to prevent temperature stratification within digesters. These cumulative energy demands can transform a net-positive energy system into one that barely breaks even during the coldest months.

5 Proven Insulation Methods to Maintain Digester Heat

Maintaining digester temperature through effective insulation represents the most cost-efficient approach to winter biogas challenges. While active heating remains important, proper insulation dramatically reduces heating energy requirements and provides resilience against temperature fluctuations. The following five methods have demonstrated consistent effectiveness across various climate zones.

1. Underground Placement of Digesters

Burying digesters underground leverages soil's natural insulating properties to maintain more stable temperatures. At depths of 1.4-1.8 meters, soil temperature fluctuates much less than ambient air temperature, providing a natural buffer against winter extremes. Studies in Northern Vietnam showed that properly buried digesters maintained temperatures 8-10°C higher than ambient air during winter months.

The effectiveness of underground placement varies with soil type and moisture content. Dry soils generally provide better insulation than wet soils, and clay-heavy soils typically offer better thermal properties than sandy soils. Digester depth optimization should consider local soil conditions and frost line depths to maximize this passive insulation benefit.

2. Styrofoam and Composite Material Wrapping

External insulation with Styrofoam or other high-R-value materials provides significant temperature retention benefits. Research indicates that a 24 cm layer of Styrofoam insulation can increase digester temperatures by 1.5-2.5°C compared to uninsulated designs. This temperature difference translates to 15-30% higher biogas production during winter months.

Modern composite insulation materials offer even better performance than traditional Styrofoam. Polyisocyanurate panels, vacuum insulated panels, and aerogel-based products provide superior R-values in thinner applications, though at higher initial cost. These advanced materials become particularly valuable for above-ground portions of digesters where space for insulation may be limited.

3. Double-Wall Construction with Air Gap

Double-wall construction creates an insulating air space between the inner digester wall and an outer protective shell. This design principle effectively combines insulation with structural protection. The air gap typically ranges from 10-25 cm and can be filled with various insulating materials or simply left as a dead air space.

The most effective double-wall systems incorporate moisture barriers to prevent condensation within the air gap, which would otherwise reduce insulation effectiveness. Some advanced designs also include reflective foil layers that reduce radiative heat loss, further improving thermal performance during winter operation.

4. Insulating Covers for Surface Areas

The surface area of digesters often represents the largest zone of heat loss, especially in cylindrical and dome-shaped designs. Specialized insulating covers that float directly on the digestate or gas collection area can reduce heat loss by 15-25%. These covers range from simple Styrofoam panels to sophisticated composite designs with integrated gas collection systems.

For smaller digesters, agricultural insulating blankets provide a cost-effective solution that can be easily applied and removed as needed. Larger commercial systems often utilize rigid dome covers with spray-applied polyurethane foam insulation on exterior surfaces. The most effective designs maintain an airtight seal while providing R-values of 30 or higher across the entire surface area.

5. Pipe Insulation and Heat Tracing Systems

Comprehensive insulation must extend beyond the digester itself to include all piping, valves, and ancillary equipment. Pre-formed pipe insulation with weatherproof jacketing provides essential thermal protection while preventing condensation and freezing. Critical areas like gas collection pipes and effluent discharge lines require particular attention to prevent system failures. For more information on maintaining biogas systems in colder climates, visit this resource on winter solutions.

Heat tracing systems that apply low-wattage heating elements along vulnerable piping provide additional protection during extreme cold events. Self-regulating heat trace cables that automatically adjust output based on ambient temperature offer the most energy-efficient solution. These systems typically consume minimal electricity while providing crucial freeze protection for the entire biogas collection network.

Heat Retention Strategies That Pay For Themselves

Beyond passive insulation, several active heat management strategies can maintain digester temperatures while offering attractive payback periods. These approaches focus on maximizing heat retention and recovery rather than simply adding external heat sources, making them particularly valuable for winter operation.

Strategic Timing of Slurry Addition (14:00 Hour Peak)

Research from Vietnam and India demonstrates that the timing of substrate additions significantly impacts digester temperature stability. Adding new substrate during peak ambient temperature (typically around 14:00 hours) allows the input material to naturally warm before introduction. This strategic timing can increase digester temperatures by 0.5-1.5°C compared to morning or evening additions.

For farm-based systems, coordinating waste collection schedules with optimal feeding times creates a no-cost improvement in winter performance. Larger operations can implement holding tanks that allow substrate to warm naturally before being transferred to the main digester. This temperature pre-conditioning reduces thermal shock and minimizes heating requirements.

Heat Exchangers and Recovery Systems

Implementing heat recovery systems that capture thermal energy from digester effluent can dramatically improve winter energy balance. Simple tube-in-tube heat exchangers can recover 40-60% of the heat that would otherwise be lost in discharged material. This recovered heat then preheats incoming substrate, reducing the temperature differential and associated heating requirements.

Advanced heat recovery systems incorporate multiple stages of heat exchange to maximize efficiency. Systems that combine effluent heat recovery with co-generation waste heat capture can maintain optimal digester temperatures with minimal external energy input, even during severe winter conditions. The capital investment in these systems typically pays back within 2-4 heating seasons through reduced heating costs and improved gas production.

Solar-Assisted Heating Options

Solar thermal systems provide complementary heating that aligns well with biogas production needs. Simple solar thermal collectors connected to heat exchangers can contribute 15-40% of winter heating requirements, depending on local climate and solar resource availability. These systems work particularly well in regions with cold but sunny winter conditions.

Hybrid approaches that combine solar thermal with geothermal heat pumps offer even greater resilience against winter temperature fluctuations. The geothermal component provides baseline heating capacity while the solar thermal system contributes supplementary heat during daylight hours. This combined approach maintains more stable digester temperatures through day/night cycles and weather changes.

Co-Generation Systems for Internal Heating

Combined heat and power (CHP) systems that burn a portion of the biogas to generate both electricity and usable heat represent one of the most efficient approaches to winter operation. Modern CHP units can achieve overall efficiency of 80-90%, with the thermal component directed to maintain digester temperatures. This self-heating approach creates a resilient system that maintains function even during extended cold periods.

The key to successful CHP implementation lies in proper sizing and control systems. Units should be sized to handle peak winter heating demands while maintaining sufficient gas production for other needs. Automated control systems that modulate CHP operation based on digester temperature provide the most efficient operation by preventing both underheating and wasteful overheating.

Payback Period for Winterization Investments

Calculating the financial return on winterization investments requires considering both avoided production losses and reduced operating costs. Most comprehensive insulation packages demonstrate payback periods of 2-4 years in moderate climates and just 1-2 years in severe cold climates. Heat recovery systems typically return their investment within 3-5 years, while co-generation systems show payback periods of 4-7 years depending on local energy prices and incentives.

Case Study: North Vietnam Biogas Plant Performance

A comprehensive study of composite digesters in Northern Vietnam provides valuable insights into winter adaptation strategies. Researchers compared insulated versus uninsulated digesters buried at 140-180 cm depths, measuring internal temperatures and biogas production throughout seasonal transitions. The insulated digesters maintained temperatures 1.5-2.5°C higher than uninsulated units, resulting in 24% higher biogas production during December-January. For more information on the anaerobic digestion process, you can explore additional resources.

The study also identified that slurry storage in mixing tanks before feeding improved performance by allowing natural warming. Digesters fed with pre-warmed substrate from afternoon storage maintained significantly higher temperatures and more stable production than those fed with freshly collected cold substrate. This simple operational change cost nothing to implement yet provided substantial production benefits during winter months. For more insights on the financial aspects of biogas systems, explore the costs of anaerobic digestion.

Regional Solutions: Biogas Success in Cold Climates

Several regions with harsh winters have developed specialized approaches to biogas production that maintain high efficiency despite challenging conditions. These region-specific solutions demonstrate that with proper design and operational adaptations, biogas can remain a reliable renewable energy source even in extreme climates.

The most successful cold-climate operations combine multiple strategies rather than relying on single solutions. Comprehensive approaches that integrate insulation, heat recovery, co-generation, and operational optimizations achieve the most consistent year-round production. These integrated systems may require higher initial investment but demonstrate superior resilience against weather extremes.

Regional approaches also reflect local economic factors and available resources. Agricultural regions often leverage abundant biomass for supplementary heating, while urban facilities might prioritize heat recovery from wastewater or industrial processes. These adaptations to local conditions and resources create more sustainable systems with improved winter performance.

Saskatoon Wastewater Treatment Plant Adaptations

The Saskatoon Wastewater Treatment Plant in Saskatchewan, Canada, operates successfully despite winter temperatures regularly dropping below -30°C. The facility employs a multi-layered approach including heavily insulated digester tanks (R-40 value), an innovative heat recovery system that captures thermal energy from effluent, and a biogas-powered CHP system that provides both electricity and process heat. This integrated approach maintains stable mesophilic conditions (35-37°C) year-round despite extreme ambient temperature fluctuations.

Northern European Biogas Facility Design

Northern European countries like Sweden, Finland, and Denmark have pioneered cold-climate biogas designs that maintain high efficiency through harsh winters. These facilities typically feature partially underground construction, extensive insulation (often exceeding 30 cm thickness), and sophisticated heat management systems. Many incorporate district heating connections that allow bidirectional heat exchange, enabling the plants to either contribute excess heat to district systems during warmer periods or draw supplementary heat during extreme cold events, creating a more resilient overall energy network.

Mountain Region Modifications

Biogas plants in mountainous regions of India, Nepal, and China have developed specialized adaptations for high-altitude cold environments. These systems often incorporate greenhouse-like enclosures that capture solar energy during daytime hours while providing wind protection and insulation. Some innovative designs in the Himalayan region have combined biogas digesters with livestock housing, using animal body heat to help maintain digester temperatures during winter months—a symbiotic arrangement that improves both energy production and animal welfare in cold conditions.

Climate Resilience: Future-Proofing Your Biogas Operation

As climate patterns become increasingly variable, building resilience into biogas operations becomes essential for long-term success. Future-proofing requires considering both gradual temperature trends and increasing frequency of extreme weather events that might disrupt normal operations. Climate-resilient designs incorporate redundant heating systems, operational flexibility, and enhanced monitoring capabilities. Learn more about the importance of anaerobic digestion as a renewable energy source to bolster your biogas operation's resilience.

Hybrid energy systems that combine biogas with other renewable sources offer particularly strong resilience against seasonal fluctuations. Systems that integrate solar thermal, heat pumps, or biomass heating provide operational flexibility that pure biogas systems lack. These hybrid approaches maintain production stability through varying conditions while often improving overall economic performance. For more insights on the benefits of biogas, check out this article on the advantages of biogas in the energy industry.

Advanced monitoring and control systems represent another crucial component of climate resilience. Remote monitoring platforms that track temperature trends, gas production rates, and microbial health indicators enable proactive management before problems develop. These systems allow operators to make data-driven decisions about feeding rates, heating adjustments, and maintenance scheduling to maintain optimal performance regardless of external conditions.

Frequently Asked Questions

The following questions address common concerns about winter biogas operation. These practical insights help operators anticipate challenges and implement appropriate solutions before production issues develop.

How much does biogas production typically drop in winter months?

Unmodified biogas systems typically experience production drops of 50-70% during winter months in cold climates. The exact reduction depends on digester design, insulation level, and the severity of temperature drops. Simple unheated digesters in subtropical regions may see production nearly cease during cold periods, while well-insulated and heated commercial systems might limit losses to 15-30% with proper adaptations.

The production curve follows ambient temperature with a lag of 1-3 weeks, depending on digester size and insulation. This lag effect means production often continues declining even after ambient temperatures begin rising, making early preparation for cold weather essential for maintaining consistent output.

What is the minimum temperature needed for anaerobic digestion to occur?

Anaerobic digestion processes can continue at temperatures as low as 5°C, but production becomes extremely limited below 10°C. Mesophilic systems operate optimally between 35-40°C, with significant production declines below 25°C. Psychrophilic microorganisms can function at lower temperatures (5-25°C) but produce gas at much slower rates, typically yielding only 20-30% of the biogas volume compared to mesophilic operations.

Are certain feedstocks better for winter biogas production?

Feedstocks with higher fat content and easily digestible carbohydrates generally perform better during winter operations. Materials like food waste, certain food processing byproducts, and fat-enriched agricultural wastes provide more energy per volume and degrade more readily at lower temperatures. These high-energy feedstocks can partially offset temperature-related efficiency losses.

Co-digestion strategies that blend multiple feedstock types often provide better winter performance than single-substrate systems. The diversity of nutrients and degradation pathways creates more resilient microbial communities that better withstand temperature fluctuations. Many successful cold-climate operations maintain feedstock storage facilities that allow strategic blending to optimize winter production.

How quickly do insulation upgrades pay for themselves through increased production?

Insulation upgrades typically demonstrate payback periods of 1-4 years, depending on climate severity and energy prices. In regions with extended winters or high energy costs, comprehensive insulation packages often pay for themselves within a single heating season through combined benefits of increased gas production and reduced heating requirements.

The economic calculation should include not just direct heating savings but also the value of avoided production losses. For commercial operations selling electricity or biomethane, maintaining winter production levels directly impacts revenue streams. These avoided revenue losses often represent the largest component of the economic return on winterization investments.

Can small-scale household digesters operate effectively in cold climates?

Small-scale household digesters can operate effectively in cold climates with appropriate adaptations. The most successful household systems in cold regions incorporate greenhouse-type enclosures, significant insulation, and strategic placement near household heat sources. Some innovative designs integrate digesters with animal shelters or kitchen areas to capture waste heat that would otherwise be lost.

For very cold climates, small-scale systems may require supplementary heating during the coldest months. Solar thermal collectors provide an economical heating option that aligns well with small-scale applications. Simple black pipe solar collectors can raise input water temperatures by 10-15°C on sunny days, significantly improving winter performance without external energy inputs.

Winter conditions can significantly affect the efficiency of biogas production. The lower temperatures can slow down the microbial activity necessary for the anaerobic digestion process, leading to reduced gas output. To mitigate this, it is crucial to understand what anaerobic digestion entails and implement strategies such as insulation and heating systems to maintain optimal conditions within the digester. By doing so, biogas facilities can continue to operate effectively even in colder climates.